Types Of Cvd Coating

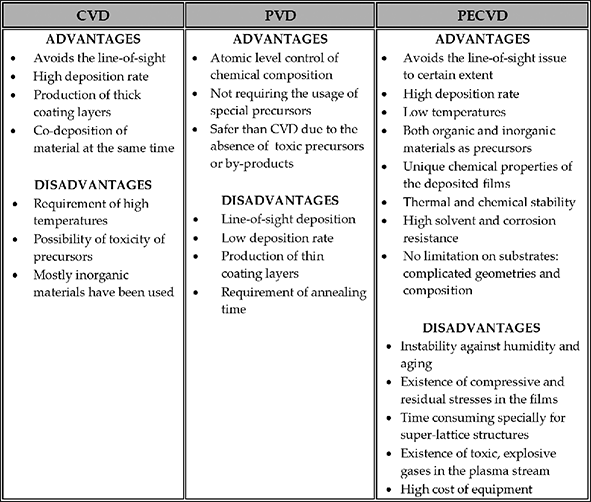

The key difference between pvd and cvd is that the coating material in pvd is in solid form whereas in cvd it is in gaseous form. Bernex chemical vapor deposition cvd coating systems set the worldwide industry standard for the enhancement of wear friction and temperature protection of tools and components.

Cvd Coatings Chemical Vapor Deposition Coatings Tic Titankote

Explained Chemical Vapor Deposition Mit News

Global Vacuum Coating Market 2019 In Depth Type Insights

1 1 2 new cvd coated grade for high speed steel turning features high crater wear resistance high flank wear resistance the gold ti compound coating on the rake face.

Types of cvd coating. Or 3 a box unit. Each configuration can be determined based on customer application. Conductive composites uses a unique and proprietary reel to reel chemical vapor deposition cvd process to place a continuous ductile conductive coating over every surface of a finished nonwoven including fibers and binders.

Our latest innovation is cvd diamond coated ceramic balls the hardest ball in the world. During this process thin film coatings are formed as the result of reactions between various gaseous phases and the heated surface of substrates within the cvd reactor. The producer system supports traditional pecvd teos and silane based oxides and nitrides and sub atmospheric cvd films as well as advanced processes including low k strain engineering litho enabling films thermal films high temperature pecvd applications sige and amorphous silicon.

2 a separate sensor head with electronics circuit. Nova diamant has a long history of producing cvd diamond for high performance mechanical applications. Pvd and cvd are coating techniques which we can use to deposit thin films on various substrates.

Chemical vapor deposition cvd is an atmosphere controlled process conducted at elevated temperatures 19250 f in a cvd reactor. Ulvacs base technology with vacuum technology at its core and related peripheral technologies have been combined through many years of rd and improvements in manufacturing technology enabling us now to deliver a very wide range of industrial manufacturing equipment for semiconductors electronic parts fpd solar cells and others. 1 an integrated sensor head with an electronics circuit.

The g tran series consists of the following 3 basic units. The first group contains treatments that penetrate the surface and generally includes the additional hardness types of treatments nitriding being the main type.

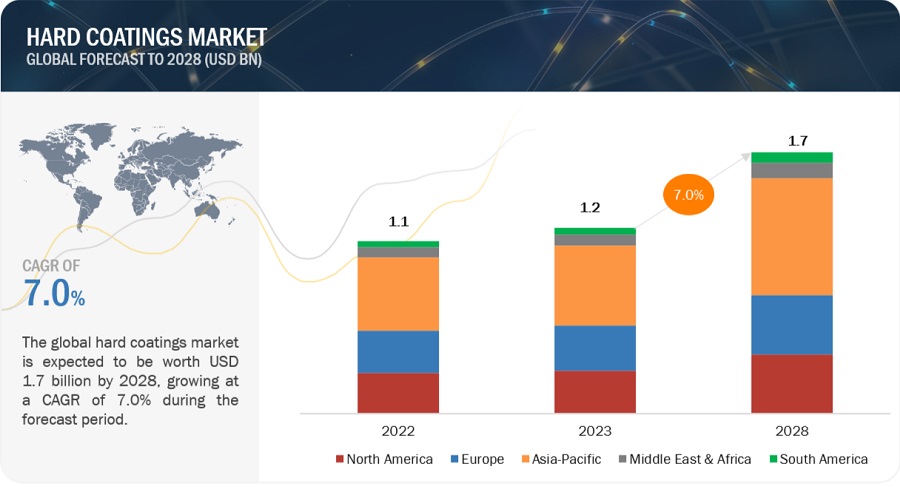

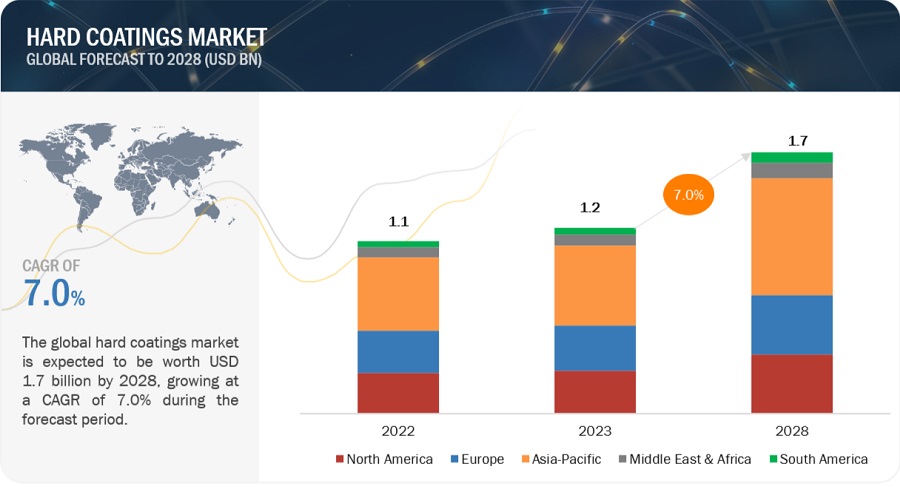

Hard Coatings Market By Application Deposition Technique Global

C Sj

Plasma Enhanced Chemical Vapor Deposition Where We Are And The

Cat Cvd Technology Hideki Matsumura Laboratory

Komentar

Posting Komentar